|

WIRING REPAIR When replacing or repairing a wire or connector, it is important that the correct gauge wire be used as shown in the service manual wiring diagrams or in the following wire substitution chart. The substitution chart shows the applicable gauge replacement wire size that can be used if necessary to substitute for the original gauge wire size.

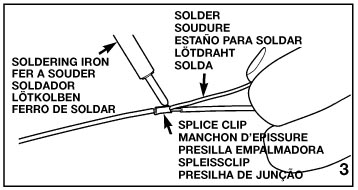

6. Solder the connection together using rosin core type

solder only

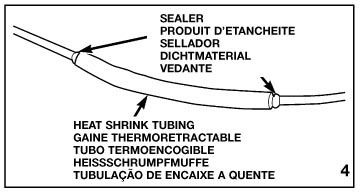

7. Center the heat shrink tubing over the splice joint

and heat using a heat

8. Secure the wire to the existing ones to prevent

chafing or damage to the 9. Connect battery and test all affected systems.

|